Products

Categories

Contact

us

Phone:0310—6700089

Fax:0310—6700061

Administration department

Phone:0310—6709999

E-mail:hbjinli@synsmc.com

Human Resources Department

Phone:0310—6700055

E-mail:hr@synsmc.com

Address:No.6 JianShe St. Industry Park,YongNian Dist. HanDan City,Hebei Prov.China

-

GELLEC Breathable Film

Product Advantage 1、Can filter virus directly, excellent protective performance. Water permeability resistance Hydrostatic pressure resistance ≥Level 4 Surface resistance to water Touch water Level ≥Level 4 Resistance to synthetic blood penetration ≥Level 3 Particulate matter(0.3μm)Filtration efficiency≥99.9%, can filter virus directly. 2、Breathable, low weight, high comfort. Moisture transmission 3500g/g㎡*d, meet long wear requirements. Breathable GURLEY values in 20~100s/100ml Low weight 4~15g/㎡can meet the protection requirements. 3、Tear resistance and wear resistance High breaking strength, the transverse breaking strength is more than 4 times that of conventional breathable film. Excellent puncture resistance,φ1mm acupuncture intensity is higher than that of conventional permeable membrane 2N Product Features 1、Mean aperture small(40-60nm), Lower than the diameter of most known bacteria and viruses,effective physical barrier, antivirus. 2、Extraction into a hole,uniform aperture,high sinuosity,barrier path length,excellent filtration efficiency. 3、The wet process is used for bidirectional high - fold drawing,pore forming uniform,the bidirectional intermolecular forces are uniform,the transverse strength is significantly better than that of conventional breathable film. 4、No or little inorganic fillers, puncture and tear resistance. 5、UHMWPE raw material, wear resistance. Features Gellec FH Series breathable film characteristics Check List Unit 9FH Series 12FH Series Conventional Breathable Film Breathable Film Composite fabric (non-woven 50gsm) Breathable Film Composite fabric (non-woven 50gsm) Breathable Film Composite fabric (non-woven 50gsm) Thickness μm 9.0 - 12.0 - - Areal Density g/m² 4.1 67 5.0 68 26 88 Air Permeability- Breathable Film sec/100ml 60 47 63 25 146 101 Air Permeability- Non-woven sec/100ml - 228 - 184 - 751 MD Breaking Strength Breathable Film N/25mm Composite fabric N/50mm 19.6 128 20.5 146 11.3 112 TD Breaking Strength Breathable Film N/25mm Composite fabric N/50mm 20.2 122 21.0 132 3.4 46 Nailing Strength N 3.1 4.3 4.0 5.0 1.0 3.8 Moisture transmission g/m2*d 3634 3740 3625 3629 2988 2938 Hydrostatic Pressure cmH2O 478 489 512 567 70 64 Filter Efficiency % 99.997 99.995 99.999 99.980 99.9 99.87 Gellec E Series breathable film characteristics Check List Unit 16E Series 20E Series Conventional Breathable Film Breathable Film Composite fabric (non-woven 50gsm) Breathable Film Composite fabric (non-woven 50gsm) Breathable Film Composite fabric (non-woven 50gsm) Thickness μm 16.0 - 20.0 - - Areal Density g/m² 8.0 75 9.5 78 26 88 Air Permeability- Breathable Film sec/100ml 46 31 43 74 146 101 Air Permeability- Non-woven sec/100ml - 144 - 148 - 751 MD Breaking Strength Breathable Film N/25mm Composite fabric N/50mm 16.9 117 16.2 120 11.3 112 TD Breaking Strength Breathable Film N/25mm Composite fabric N/50mm 16.2 126 15.7 92 3.4 46 Nailing Strength N 1.3 3.7 1.3 3.8 1.0 3.2 Moisture transmission g/m2*d 3598 3672 3435 3491 2988 2938 Hydrostatic Pressure cmH2O 631 639 604 618 70 64 Filter Efficiency % 99.996 99.982 99.995 99.970 99.9 99.87

-

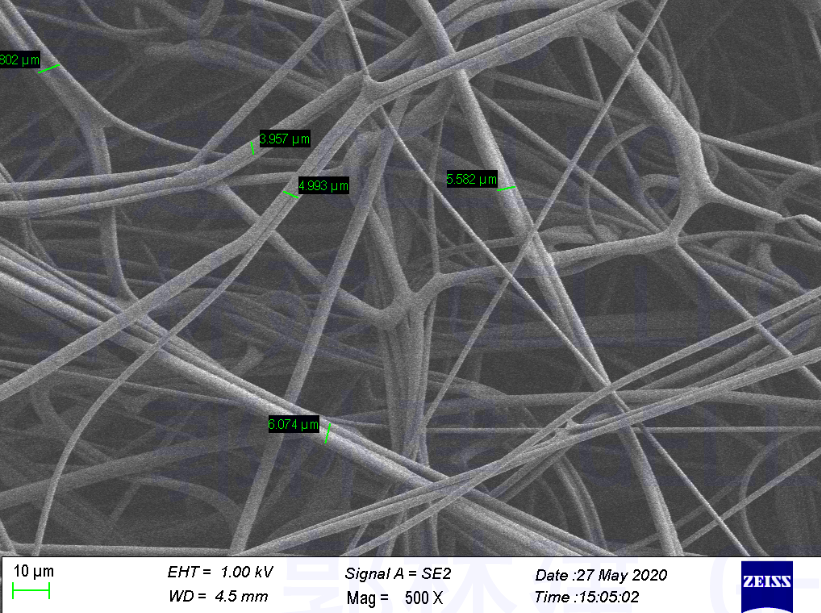

KN series melt blown cloth

1. Product Features ◆ Take polypropylene special resin as raw material, the non-woven are made by GELLEC unique high temperature melting and spraying process. ◆ Microfiber, lager specific surface area, high porosity, smooth, soft, good folding resistance. ◆ High filtration efficiency, good air permeability, small respiratory resistance. ◆ The electret is stable, the static electricity does not disappear in most applications, and the filtration performance is stable. ◆ Has good thermal insulation performance, water and oil absorption, has a good flame retardant performance. ◆ Non-toxic, tasteless, Non-irritating, white and light. 2. Product Performance Performance KN90 KN95 KN100 1 g/m2 40±50± 5%2 % 92.4 100 Air resistance GB 2626 72 4 Longitudinal 12.9 12.9 5 N 9.4 36.1 Breaking elongation GB/T 24218.3 39

-

BFE Series Melt Blown Cloth

1. Product Features ◆ Take polypropylene special resin as raw material, the non-woven are made by GELLEC unique high temperature melting and spraying process. ◆ Microfiber, lager specific surface area, high porosity, smooth, soft, good folding resistance. ◆ High filtration efficiency, good air permeability, small respiratory resistance. ◆ The electret is stable, the static electricity does not disappear in most applications, and the filtration performance is stable. ◆ Has good thermal insulation performance, water and oil absorption, has a good flame retardant performance. ◆ Non-toxic, tasteless, Non-irritating, white and light. 2. Product Performance Performance Test Standard BFE95 BFE99 1 g/m2 25±7% 25 Bacterial filtration efficiency - BFE YY0469 ≥96.8 3 % 30 97.8 Air resistance YY0469 21 5 Longitudinal GB/T 24218.3 12.1 6 N ≥6 8.9 Breaking elongation GB/T 24218.3 34

-

Polypropylene Melting Spray Special Material

1. Applicable Models:PPH-Y1500 MAIN FEATURES • Excellent machining performance • The melt mass flow rate is stable • Narrow molecular weight distribution MAIN APPLICATIONS • Melt blown non-woven fabric • Masks, protective clothing, etc 2.Property Values Properties Units Test Standard Test Condition Typical Value Melt Flow Rate g/10min GB/T 3682 230℃,2.16Kg 1500 Melting Point ℃ GB/T 19466.3 10℃/min 163℃ Density g/cm3 GB/T 1033.1 Immersion method, room temperature 0.9 ASH % GB/T 9345.1 850℃ 0.024 Volatilc constitucnts % GB/T 2914 110℃ <0.2 Note:The above data are all experimental typical values, true and reliable. They are only use as reference data and cannot be considered as the lower limit of material properties.

-

Electret Masterbatch

Technical Indicators Heat-resistance temperature:280℃Characteristics of density:0.90±0.03g/cm3 Melt index:≥500g/10min(230℃,2.16kg) 2. The product is a electret master granule with homo-polypropylene as the carrier, The purpose of electret is to make the melting spray layer in the mask non-woven 3. Series of BFE:1.0-1.5% Series of N95/N98/P1/P2:2.5-3.0% Usage with the masterbatch feeding metering device. There are several kinds of charging power supply: filter air electrostatic field generation power supply, 5. The effect of electret is related to the polypropylene melting and spraying materials, production process, Note: The above date are all typical experimental values and only use as reference data.

-

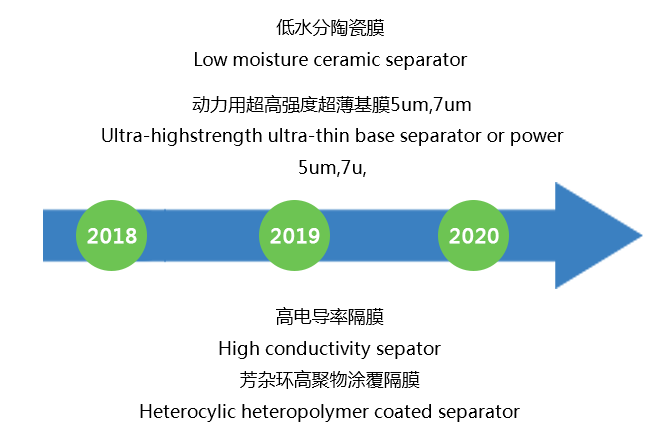

Third generation product